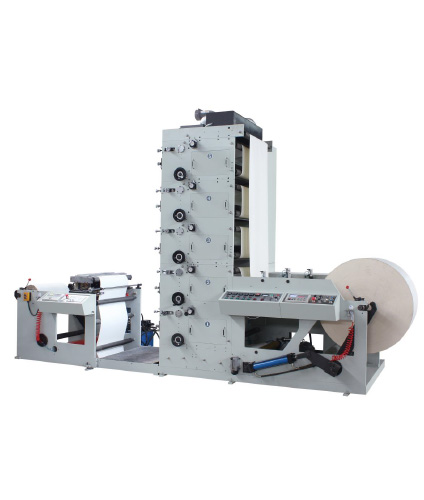

4 color Flexo Printing Machine GI -850

- Adopt the anilox roller to spread ink.

- Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

- Each printing unit adopt 360°for registration.

- Each printing unit have one IR dryer.

- The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

- The main motor is adopted the import stepless regulation of frequency conversion.

- Unwinding, web guiding, printing, IR drying and rewinding can be finished in one process. This is an ideal machine for printing factory to print many kinds of paper cup.

Call For a Quote:

(+91) 8810-612-987

| Web width : | 500mm |

| Max.bag making length: | 850mm |

| Print width: | 840mm |

| Unwind Diameter max: | 1000mm |

| Rewind Diameter max: | 1000mm |

| Press Speed max (Production speed depending on process, job etc.): | 70m/min |

| Gear Pitch: | 1/8” (3.175mm) |

| Flexo Print Units (UV dryer): | 4 |

| Min.Max repeat (Print Cylinder): | 10" - 22.5" |

| Web Guiding: | Number 1 |

| Corona treatment: | Number 1 (for doube PE coated paper) |

| Overprint precision: | ±0.15mm |

| Dimensions: | 33600*1820*2350mm |

| Weight: | 5000kg |